|

|||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||

|

¡å Hydraulical Diaphragm Dosing Pump [ FIM1 Serise ]

|

|||||||||||||||||||||||||||

|

¡å Hydraulical Diaphragm Dosing Pump [

FIM2R Serise ]

|

|||||||||||||||||||||||||||

|

¡å Hydraulical Diaphragm Dosing Pump [

FIE1R Serise ]

|

|||||||||||||||||||||||||||

|

¡å Hydraulical Diaphragm Dosing Pump [ FIE2 Serise ]

|

|||||||||||||||||||||||||||

|

¡å Hydraulical Diaphragm Dosing Pump [ FIE3 Serise ]

|

|||||||||||||||||||||||||||

|

¡å Plunger Dosing

Pump [ 10P Serise ]

|

|||||||||||||||||||||||||||

¡å Plunger Process Pump [ R & C Serise

]

|

|||||||||||||||||||||||||||

|

¡å Plunger Dosing Pump [ M1 Serise ]

|

|||||||||||||||||||||||||||

|

¡å Plunger Dosing Pump [ M2R Serise ]

|

|||||||||||||||||||||||||||

|

¡å Plunger

Dosing Pump [ E1R Serise ]

|

|||||||||||||||||||||||||||

|

¡å Plunger Dosing Pump [ E2 Serise ]

|

|||||||||||||||||||||||||||

¡å Plunger Dosing Pump [ E3 Serise ]

|

Model

|

À¯ ·® (Flow rate)

|

Max Pressure

|

|

L/Hr(LPH)

|

bar

|

||

|

E3 STA

|

387~4107

|

40

|

|

|

E3 STB

|

387~1980

|

85

|

|

|

E3 SBF-SBB

|

30~672

|

200(Special:471)

|

|

|

E3DE S*A

|

685~16569

|

40(Special:95)

|

|

|

¡ØE3DE S*A

: Double acting piston ±×¿Ü Model : Plunger

acting with SUS pump Head

|

|||

|

ETATRON ȍ

|

¢Â Solenoid Dosing Pump [ PB Series ]

| PB-MA PB-MA is a costant Manual/ON-OFF mode dosing pump. The pump flow can be controlled manually by setting the pump pulse rate by means of a potentiometer. ? Pulse rate adjustable from 0 to 100%. ? A frequency switch reduces of 1/5 scale of the flow potentiometer consequently the number of injections per minute for accurate control of low output. |

|||||

|

PB-F |

|||||

|

PB-CC |

|||||

|

PB-MA |

PB-F |

PB-CC |

PB-VFT |

PB-PH |

PB-RX |

| PB-VFT This pump incorporates a microprocessor unit providing four different operating modes: MODE 1 - MANUAL: Pulse frequency adjustment. Pulse rate is clearly indicated. Max. pulse/min. 100 MODE 2 - Multiplier(1x n/M): the pump unit receives a pulse from an external source (I.E. water meter). For each pulse received the pump will effect the number of injections selected by the operator. In the instance where a second pulse is received before the pump unit has completed the cycle, the pump retains this external pulse within its memory and re-starts at the end of the completed cycle. This is particularly suited for high concentration dosing. MODE 3 - MULTIPLIER (1xn): As MODE 2 but an external pulse received whilst carrying out a cycle is not retained within the memory but is ignored. MODE 4 - DIVIDER (1:n): the pump counts the number of external pulses received until reaching the value set by the operator, at which point the pump will effect one injection. |

|||||

| PB-PH his unit is a dosign pump with integral pH controller designed to measure, control and regulate the pH value. The PB-PH pump utilise an ON-Off mode to stop dosing once the pH value reaches the Set point. Measuring range: 0-14 pH. |

|||||

| PB-RX This unit is a dosign pump with integral RX (ORP) controller designed to measure, control and regulate the Redox value. The PB-RX pump utilise an ON-Off mode to stop dosing once the RX value reaches the Set point. Measuring range: - 1.400 + 1.400 mV. |

|||||

| HD

series incorporates an internal transformer

reducing main supply to 48V extending operational life providing protection

against mains voltage fluctuations and assuring a reliable and steady functioning. Suitable for heavy duties and industrial applications. A die-cast aluminium housing allows the pump to reach high pulse frequency |

||||||

| HD-PM The HD-PM dosing pump can operate in either Manual or Proportional mode. Connected to a pulse emitting device, this unit is able to dose the additive in accordance with a pre-selected PPM value. A multiturn potentiometer enable precise setting of PPM required or altenatively in manual mode, selects the pulse rate. This unit can operate with any type of pulse emitting device, most commonly water meters: 1 imp/10 l; 1 imp/l; 2 imp/l; 4 imp/l. The HD series incorporates an internal transformer reducing main supply to 48V extending operational life providing protection against mains voltage fluctuations. Suitable for heavy duties and industrial applications. |

||||||

| HD-MA

This unit is a costant Manual/ON-OFF mode dosing pump. The pump flow can be controlled manually by setting the pump pulse rate by means of a potentiometer. ? Pulse rate adjustable from 0 to 100%. ? A frequency switch reduces of 1/5 scale of the flow potentiometer consequently the number of injections per minute for accurate control of low output. The HD series incorporates an internal transformer reducing main supply to 48V extending operational life providing protection against mains voltage fluctuations. Suitable for heavy duties and industrial applications. |

||||||

| HD-PH

This unit is a dosign pump with integral pH controller designed to measure, control and regulate the pH value. The HD-PH pump utilise an ON-Off mode to stop dosing once the pH value reaches the Set point. Measuring range: 0-14 pH. The HD series incorporates an internal transformer reducing main supply to 48V extending operational life providing protection against mains voltage fluctuations. Suitable for heavy duties and industrial applications. |

||||||

HD-PM

HD-PM

|

HD-MA

HD-MA |

HD-PH |

HD-MA/T |

HD-PH/P |

HD-VF |

HD-RX |

| HD-MA/T The HD-MA/T can operate in either in Manual or Proportional mode. The proportional mode is Multiplier (1x n) type: connected to a pulse emitting device, for each pulse received the pump will effect the number of injections selected by the operator and operate for the time selected via a timer from 0-60 seconds. The HD series incorporates an internal transformer reducing main supply to 48V extending operational life providing protection against mains voltage fluctuations. Suitable for heavy duties and industrial applications. |

||||||

| HD-PH/P

This unit is a dosign pump with integral PH controller designed to measure, control and regulate the pH value. The HD-PH/P pump utilise a proportional mode: this pump reduces pulse frequency as it nears to the Set-point selected by the operatore. Measuring range: 0-14 pH. The HD series incorporates an internal transformer reducing main supply to 48V extending operational life providing protection against mains voltage fluctuations. Suitable for heavy duties and industrial applications. |

||||||

| HD-VF The HD-VF is a "Divider" (1:n) Proportional dosing pump. When connected to a pulse emitting water meter, the unit counts the number of external pulses received until reaching the value set by the operator ( max set-point to 999 units), at which point the pump wil l effect one injection. This pump unit will operate in relation to any type of pulse emitting device, most commonly a water meter. The HD series incorporates an internal transformer reducing main supply to 48V extending operational life providing protection against mains voltage fluctuations. Suitable for heavy duties and industrial applications. |

||||||

| HD-RX

This unit is a dosign pump with integral RX (ORP) controller designed to measure, control and regulate the Redox value. The HD-RX pump utilise an ON-Off mode to stop dosing once the RX value reaches the Set point. Measuring range:- 1.400 + 1.400 mV. The HD series incorporates an internal transformer reducing main supply to 48V extending operational life providing protection against mains voltage fluctuations. Suitable for heavy duties and industrial applications. |

||||||

|

MC-mA |

The MC-mA dosing pump

can be connected to a transmitter /indicator instrument or other device which supplies a modulated current signal from 4(0) to 20 mA. The pump impulse frequency rate will be proportional to the mA signal received: higher the signal higher the pump flow. The pump can be adapted for inverse operation: to the higher signal corresponds to the lowest flow. Same model can be adapted for different mA signals: 0-20 mA;4-20 mA; 20-4 mA. Various functioning modes are available according to system requirements. PLEASE NOTE: pump input impedance value Max.255 The pump can be adapted for inverse operation: to the higher signal corresponds to the lowest flow. Same model can be adapted for different mA signals: 0-20 mA; 4-20 mA; 20-4 mA. Various functioning modes are available according to system requirements. PLEASE NOTE: pump input impedancevalue Max.255 |

|

MC-CI |

The MC-Cl is a microprocessor based

proportional unit able to analized the "Free chlorine residual"

and dose according to requirements. The pump flow is controlled

via an external mA signal emitted by a Chlorine Cell with transmitter

specially designed to wrok with this unit. The

signal is comprised between 0 and 20 mA selected by the operator.

The pump injects chlorine, proportionally to the external

mA signal until reaches the "Set-point 1" previously selected

|

DL-MA |

DL-F |

DL2-MA |

DL-PM |

[ DL-MA ]This unit is a costant Manual/ON-OFF mode dosing pump. The pump flow can be controlled manually by setting the pump pulse rate by means of a potentiometer. ? Pulse rate adjustable from 0 to 100%. ? A frequency switch reduces of 1/5 scale of the flow potentiometer consequently the number of injections per minute for accurate control of low output. |

|||

[ DL-F ]The dosing pump can function in two modes: PROPORTIONAL MODE: it's controlled by an external pulse received by a pulse transmitter (E.g. pulse emitting water meter); for each pulse received there will be an injection (1:1). MANUAL/ON-OFF MODE: the pump flow rate can be controlled manually by setting the pump pulse frequency from 0 to 100% by means of a potentiometer. |

|||

[ DL2-MA ]This unit features two dosing pump heads comprised into one housing. It's a costant Manual/ON-OFF modes dosing pump. Flow can be controlled manually by adjusting pump pulse rate from 0 to 100%. Individual adjustment is provided for each pump head. |

|||

[ DL-PM ] DL-PM dosing pump can work in either Manual or Proportional modes. Connected to a pulse emitting water meter, this unit is able to dose the additive in accordance with a pre-selected PPM value. This pump can function to any type of pulse emitting device and is also adapted to the most commonly used water meters: 1 imp/10 l; 1 imp/l; 2 imp/l; 4 imp/l. |

|||

|

DL-LIS/E |

DL-LIS/CDM |

DL-PK |

DL-PK/IP65 |

[ DL-LIS/E ]This unit is a costant Manual/ON-OFF mode dosing pump. The pump flow can be controlled manually by setting the pump pulse rate by means of a potentiometer. ? Pulse rate adjustable from 0 to 100%. ? A frequency switch reduces of 1/5 scale of the flow potentiometer consequently the number of injections per minute for accurate control of low output. |

|||

[ DL-LIS/CDM ]This is a dosign pump with integral CD controller designed to measure, control and regulate the Conductivity value. The DL-LIS/CDM pump utilise an ON-Off mode to stop dosing once the CD value reaches the Set point. This unit also feature a Direct/Reverse mode selector to suit requirements. Measuring range: 100-20.000 microSiemens |

|||

|

Pulse rate adjustable from |

|||

[ DL-PK/IP65 ]This is a compact versatile dosing pump with IP 65 rating. The unit function with costant Manual/ON-OFF mode. The pump flow can be controlled manually by setting by the pump pulse rate via an internal potentiometer protected by an external rubber cap. Pulse rate adjustable from 0 to 100%. |

|||

|

Solenoid

driven dosing pump specifically designed for dishwasher machine cycles

dosing requirements with the advantage of being controlled directly

by two solenoid valves, thus allowing two independent flow adjustment. It can be connected and directly controlled by a solenoid valve. Wall mounting. Compact ABS plastic housing Standard power supply: Other power supply available upon request: |

||||||||

|

Model

|

Max flow

|

Max

Pressure |

Max freq.

|

ml o cc

per pulse |

net

weight |

Dimension

|

|||

|

height

|

width

|

depth

|

|||||||

|

L/h

|

ml/min

|

bar

|

lmp/min

|

-

|

kg

|

mm

|

mm

|

mm

|

|

|

PK-D/2EV

01-05 |

1

|

16.7

|

5

|

100

|

0.16

|

2.3

|

150

|

108

|

110

|

|

PK-D/2EV

02-03 |

2

|

33.3

|

3

|

100

|

0.33

|

2.3

|

163

|

108

|

110

|

|

PK-D/2EV

04-01 |

4

|

66.7

|

1

|

100

|

0.66

|

2.3

|

163

|

108

|

110

|

|

Lquid Ends Material

|

FILTER:

Stainless Steel SUCTION HOSE: pvc "cristal" DISCHARGE HOSE: polyethylene NIPPLES: polypropilene PUMP HEAD: polypropilene |

"LIP"

VALVE: Dutral? (upon request Viton) DIAPHRAGM: teflon?DIAPHRAGM "O"RING SEAL: Dutral? (upon request Viton?) INJECTION VALVE FITTING: polypropilene |

|||||||

|

Solenoid driven dosing

pump specifically designed for dishwasher machine cycles dosing requirements.

It can be connected and directly controlled by a solenoid valve. Wall mounting. Compact ABS plastic housing Standard power supply: Other power supply available upon request: |

||||||||

|

Model

|

Max flow

|

Max

Pressure |

Max freq.

|

ml o cc

per pulse |

net

weight |

Dimension

|

|||

|

height

|

width

|

depth

|

|||||||

|

L/h

|

ml/min

|

bar

|

lmp/min

|

-

|

kg

|

mm

|

mm

|

mm

|

|

|

PK-D

01-05 |

1

|

16.7

|

5

|

100

|

0.16

|

2.3

|

150

|

108

|

110

|

|

PK-D

02-03 |

2

|

33.3

|

3

|

100

|

0.33

|

2.3

|

163

|

108

|

110

|

|

PK-D

04-01 |

4

|

66.7

|

1

|

100

|

0.66

|

2.3

|

163

|

108

|

110

|

|

Lquid Ends Material

|

|

|

|||||||

|

Head Description/Application

|

Dimension

|

|||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||

|

Model

|

l/h

|

Pressure

|

Motor Power

|

Piston diameter

|

Strokes / min

|

Piston stroke

|

Valve type

|

Connections

|

||

|

bar

|

psi

|

kw

|

mm

|

mm

|

||||||

| MP0010AA |

10

|

20

|

290

|

0.18

|

17

|

58

|

12.5

|

AB5 DV A*

|

1/2" Gm**

|

|

| MP0020AA |

20

|

20

|

290

|

0.18

|

17

|

116

|

12.5

|

AB5 DV A

|

1/2" Gm

|

|

| MP0022AA |

22

|

20

|

290

|

0.18

|

25

|

58

|

12.5

|

AB5 DV A

|

1/2" Gm

|

|

| MP0044AA |

44

|

20

|

290

|

0.18

|

25

|

116

|

12.5

|

AB5 DV A

|

1/2" Gm

|

|

| MP0031AA |

31

|

14

|

203

|

0.18

|

30

|

58

|

12.5

|

AB6 A

|

1/2" Gm

|

|

| MP0062AA |

62

|

14

|

203

|

0.18

|

30

|

116

|

12.5

|

AB6 A

|

1/2"Gm

|

|

| MP0050AA |

50

|

9

|

130

|

0.18

|

38

|

58

|

12.5

|

AB8 A

|

1/2" Gm

|

|

| MP0100AA |

100

|

9

|

130

|

0.18

|

38

|

116

|

12.5

|

AB8 A

|

1/2" Gm

|

|

| MP0078AA |

78

|

5

|

72

|

0.18

|

47

|

58

|

12.5

|

AB8 A

|

1/2" Gm

|

|

| MP0156AA |

156

|

5

|

72

|

0.18

|

47

|

116

|

12.5

|

AB8 A

|

1/2" Gm

|

|

| MP0083AA |

83

|

13

|

188

|

0.25

|

38

|

70

|

17.5

|

AB8 A

|

1/2" Gm

|

|

| MP0144AA |

144

|

13

|

188

|

0.25

|

38

|

120

|

17.5

|

AB8 A

|

1/2" Gm

|

|

| MP0130AA |

130

|

8

|

116

|

0.25

|

47

|

70

|

17.5

|

AB8 A

|

1/2" Gm

|

|

| MP0226AA |

226

|

8

|

116

|

0.25

|

47

|

120

|

17.5

|

AB8 A

|

1/2" Gm

|

|

| MP0168AA |

168

|

6

|

87

|

0.25

|

54

|

70

|

17.5

|

AB13 A

|

3/4" Gm

|

|

| MP0290AA |

290

|

6

|

87

|

0.25

|

54

|

120

|

17.5

|

AB13 A

|

3/4" Gm

|

|

| MP0236AA |

236

|

4

|

58

|

0.25

|

64

|

70

|

17.5

|

AB13 A

|

3/4" Gm

|

|

| MP0408AA |

408

|

4

|

58

|

0.25

|

64

|

120

|

17.5

|

AB13 A

|

3/4" Gm

|

|

| MP0010BA |

10

|

10

|

145

|

0.18

|

17

|

58

|

12.5

|

AB4 DV P*

|

1/2" Gm**

|

|

| MP0020BA |

20

|

10

|

145

|

0.18

|

17

|

116

|

12.5

|

AB4 DV P

|

1/2" Gm

|

|

| MP0022BA |

22

|

10

|

145

|

0.18

|

25

|

58

|

12.5

|

AB5 DV P

|

1/2" Gm

|

|

| MP0044BA |

44

|

10

|

145

|

0.18

|

25

|

116

|

12.5

|

AB5 DV P

|

1/2" Gm

|

|

| MP0031BA |

31

|

10

|

145

|

0.18

|

30

|

58

|

12.5

|

AB8 DV P

|

1/2" Gm

|

|

| MP0062BA |

62

|

10

|

145

|

0.18

|

30

|

116

|

12.5

|

AB8 DV P

|

1/2"Gm

|

|

| MP0050BA |

50

|

9

|

130

|

0.18

|

38

|

58

|

12.5

|

AB8 DV P

|

1/2" Gm

|

|

| MP0100BA |

100

|

9

|

130

|

0.18

|

38

|

116

|

12.5

|

AB8 DV P

|

1/2" Gm

|

|

| MP0078BA |

78

|

5

|

72

|

0.18

|

47

|

58

|

12.5

|

AB8 DV P

|

1/2" Gm

|

|

| MP0156BA |

156

|

5

|

72

|

0.18

|

47

|

116

|

12.5

|

AB8 DV P

|

1/2" Gm

|

|

| MP0083BA |

83

|

10

|

145

|

0.25

|

38

|

70

|

17.5

|

AB8 DV P

|

1/2" Gm

|

|

| MP0144BA |

144

|

10

|

145

|

0.25

|

38

|

120

|

17.5

|

AB8 DV P

|

1/2" Gm

|

|

| MP0130BA |

130

|

8

|

116

|

0.25

|

47

|

70

|

17.5

|

AB8 DV P

|

1/2" Gm

|

|

| MP0226BA |

226

|

8

|

116

|

0.25

|

47

|

120

|

17.5

|

AB8 DV P

|

1/2" Gm

|

|

| MP0168BA |

168

|

6

|

87

|

0.25

|

54

|

70

|

17.5

|

AB13 P

|

3/4" Gm

|

|

| MP0290BA |

290

|

6

|

87

|

0.25

|

54

|

120

|

17.5

|

AB13 P

|

3/4" Gm

|

|

| MP0236BA |

236

|

4

|

58

|

0.25

|

64

|

70

|

17.5

|

AB13 P

|

3/4" Gm

|

|

| MP0408BA |

408

|

4

|

58

|

0.25

|

64

|

120

|

17.5

|

AB13 P

|

3/4" Gm

|

|

|

Head description/Application

|

Dimension

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1.Valve 2.Diaphragm 3.Head [M.Diaphragm PumpÀû¿ë] - Zero leakage is essential. - Pumped liquid is abrasive - And contains suspended solids particles. |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Model

|

À¯·®

|

¾Ð·Â

|

Motor

Power |

Diaphragm

Diamter |

Stroke

/min |

Diaphragm

stroke |

Valve

type |

¿¬°á

|

|

|

l/h

|

bar

|

kw

|

mm

|

-

|

mm

|

-

|

-

|

||

|

DMA075AA

|

75

|

5

|

0.18

|

70

|

58

|

10

|

AB8 A

|

1/2" Gm

|

|

|

DMA150AA

|

150

|

5

|

0.18

|

70

|

116

|

10

|

AB8 A

|

1/2" Gm

|

|

|

DMA115AA

|

115

|

3

|

0.18

|

90

|

58

|

10

|

AB11 A

|

3/4" Gm

|

|

|

DMA230AA

|

230

|

3

|

0.18

|

90

|

116

|

10

|

AB11 A

|

3/4" Gm

|

|

|

DMA156AA

|

156

|

1.5

|

0.18

|

105

|

58

|

10

|

AB13 A

|

3/4" Gm

|

|

|

DMA298AA

|

298

|

1.5

|

0.18

|

105

|

116

|

10

|

AB13 A

|

3/4" Gm

|

|

|

DMA177AA

|

177

|

1.5

|

0.18

|

120

|

58

|

10

|

AB17 A

|

1" Gm

|

|

|

DMA374AA

|

374

|

1.5

|

0.18

|

120

|

116

|

10

|

AB17 A

|

1" Gm

|

|

|

DMB090AA

|

90

|

8

|

0.25

|

70

|

70

|

10

|

AB8 A

|

1/2" Gm

|

|

|

DMB154AA

|

154

|

8

|

0.25

|

70

|

120

|

10

|

AB8 A

|

1/2" Gm

|

|

|

DMB148AA

|

148

|

5

|

0.25

|

90

|

70

|

10

|

AB11 A

|

3/4" Gm

|

|

|

DMB255AA

|

255

|

5

|

0.25

|

90

|

120

|

10

|

AB11 A

|

3/4" Gm

|

|

|

DMB201AA

|

201

|

3

|

0.25

|

105

|

70

|

10

|

AB13 A

|

3/4" Gm

|

|

|

DMB331AA

|

331

|

3

|

0.25

|

105

|

120

|

10

|

AB13 A

|

3/4" Gm

|

|

|

DMB225AA

|

225

|

3

|

0.25

|

120

|

70

|

10

|

AB17 A

|

1" Gm

|

|

|

DMB408AA

|

408

|

3

|

0.25

|

120

|

120

|

10

|

AB17 A

|

1" Gm

|

|

|

DMA075BA

|

75

|

5

|

0.18

|

70

|

58

|

10

|

AB8 DV P

|

1/2" Gm

|

|

|

DMA150BA

|

150

|

5

|

0.18

|

70

|

116

|

10

|

AB8 DV P

|

1/2" Gm

|

|

|

DMA115BA

|

115

|

3

|

0.18

|

90

|

58

|

10

|

AB11 P

|

3/4" Gm

|

|

|

DMA230BA

|

230

|

3

|

0.18

|

90

|

116

|

10

|

AB11 P

|

3/4" Gm

|

|

|

DMA156BA

|

156

|

1.5

|

0.18

|

105

|

58

|

10

|

AB13 P

|

3/4" Gm

|

|

|

DMA298BA

|

298

|

1.5

|

0.18

|

105

|

116

|

10

|

AB13 P

|

3/4" Gm

|

|

|

DMA177BA

|

177

|

1.5

|

0.18

|

120

|

58

|

10

|

AB17 P

|

1" Gm

|

|

|

DMA374BA

|

374

|

1.5

|

0.18

|

120

|

116

|

10

|

AB17 P

|

1" Gm

|

|

|

DMB090BA

|

90

|

8

|

0.25

|

70

|

70

|

10

|

AB8 DV P

|

1/2" Gm

|

|

|

DMB154BA

|

154

|

8

|

0.25

|

70

|

120

|

10

|

AB8 DV P

|

1/2" Gm

|

|

|

DMB148BA

|

148

|

5

|

0.25

|

90

|

70

|

10

|

AB11 P

|

3/4" Gm

|

|

|

DMB255BA

|

255

|

5

|

0.25

|

90

|

120

|

10

|

AB11 P

|

3/4" Gm

|

|

|

DMB201BA

|

201

|

3

|

0.25

|

105

|

70

|

10

|

AB13 P

|

3/4" Gm

|

|

|

DMB331BA

|

331

|

3

|

0.25

|

105

|

120

|

10

|

AB13 P

|

3/4" Gm

|

|

|

DMB225BA

|

225

|

3

|

0.25

|

120

|

70

|

10

|

AB17 P

|

1" Gm

|

|

|

DMB408BA

|

408

|

3

|

0.25

|

120

|

120

|

10

|

AB17 P

|

1" Gm

|

|

DM-AA |

|

|

DM-BA

|

DV: Double ball check valve - P: PVC; **Gm: Gas male USEFUL information for selection of dosing pumps: Max flow rate, Max working pressure, chemical viscosity, specific gravity (S.G.), tem-perature, area classification, suspended solids in chemical. Note: out of standard configuration code shall be indicated only by Etatron authorized staff upon request. |

|

Head description/Application

|

Dimension/Application

|

||||||||||||||||||||||||||

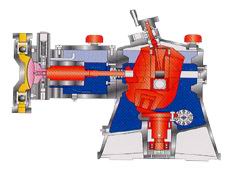

Pump head is connected to the gearbox via a spacer assembly. Standard pump head materials are PVC and SS316. Other materials are available upon request. Stainless Steel 420 T standard plunger Polyuretan elastomer gaskets (NOVATAM T 20) Single and double ball check valves assembly designed for easy inspection and access. Standard connections "Gm" threaded Gas male/BSPm; Flanged connections are available. MD SERIES VARIATIONS: DE series: the diaphragm hydraulic chamber is made of PVC against external corrosive environment. MULTIPLE SYSTEMS: available upon request up to 5 heads; each pump group is indepen-dently adjustable. For the above variations or other requirements please contact our customer service departement |

Hydraulic diaphragm type pumps Application -

Zero leakage is essential. |

||||||||||||||||||||||||||

|

Model

|

À¯·®

|

¾Ð·Â

|

Motor

Power |

Diaphragm

Diamter |

Stroke

/min |

Diaphragm

stroke |

Valve

type |

¿¬°á

|

|

|

l/h

|

bar

|

kw

|

mm

|

-

|

mm

|

-

|

-

|

||

|

MD0011AA

|

11

|

20

|

0.18 kW

|

18 mm

|

58

|

12.5

|

AB5 DV A* | 1/2" Gm** | |

|

MD0022AA

|

22

|

20

|

0.18 kW

|

18 mm

|

116

|

12.5 mm

|

AB5 DV A | 1/2" Gm | |

|

MD0021AA

|

21

|

20

|

0.18 kW

|

25 mm

|

58

|

12.5 mm

|

AB5 DV A | 1/2" Gm | |

|

MD0042AA

|

42

|

20

|

0.18 kW

|

25 mm

|

116

|

12.5 mm

|

AB5 DV A | 1/2" Gm | |

|

MD0030AA

|

30

|

14

|

0.18 kW

|

30 mm

|

58

|

12.5 mm

|

AB6 A | 1/2" Gm | |

|

MD0060AA

|

60

|

14

|

0.18 kW

|

30 mm

|

116

|

12.5 mm

|

AB6 A | 1/2"Gm | |

|

MD0054AA

|

54

|

8

|

0.18 kW

|

40 mm

|

58

|

12.5 mm

|

AB8 A | 1/2" Gm | |

|

MD0108AA

|

108

|

8

|

0.18 kW

|

40 mm

|

116

|

12.5 mm

|

AB8 A | 1/2" Gm | |

|

MD0051AA

|

51

|

20

|

0.25 kW

|

30 mm

|

70

|

17.5 mm

|

AB6 A | 1/2" Gm | |

|

MD0088AA

|

88

|

20

|

0.25 kW

|

30 mm

|

120

|

17.5 mm

|

AB6 A | 1/2" Gm | |

|

MD0092AA

|

92

|

12

|

0.25 kW

|

40 mm

|

70

|

17.5 mm

|

AB8 A | 1/2" Gm | |

|

MD0158AA

|

158

|

12

|

0.25 kW

|

40 mm

|

120

|

17.5 mm

|

AB8 A | 1/2" Gm | |

|

MD0144AA

|

144

|

7

|

0.25 kW

|

50 mm

|

70

|

17.5 mm

|

AB11 A | 3/4" Gm | |

|

MD0247AA

|

247

|

7

|

0.25 kW

|

50 mm

|

120

|

17.5 mm

|

AB11 A | 3/4" Gm | |

|

MD0174AA

|

174

|

6

|

0.25 kW

|

55 mm

|

70

|

17.5 mm

|

AB13 A | 3/4" Gm | |

|

MD0299AA

|

299

|

6

|

0.25 kW

|

55 mm

|

120

|

17.5 mm

|

AB13 A | 3/4" Gm | |

|

MD0243AA

|

243

|

4

|

0.25 kW

|

65 mm

|

70

|

17.5 mm

|

AB13 A | 3/4" Gm | |

|

MD0418AA

|

418

|

4

|

0.25 kW

|

65 mm

|

120

|

17.5 mm

|

AB13 A | 3/4" Gm | |

|

MD0011BA

|

11

|

10

|

0.18 kW

|

18 mm

|

58

|

12.5 mm

|

AB4 DV P* | 1/2" Gm** | |

|

MD0022BA

|

22

|

10

|

0.18 kW

|

18 mm

|

116

|

12.5 mm

|

AB4 DV P | 1/2" Gm | |

|

MD0021BA

|

21

|

10

|

0.18 kW

|

25 mm

|

58

|

12.5 mm

|

AB5 DV P | 1/2" Gm | |

|

MD0042BA

|

42

|

10

|

0.18 kW

|

25 mm

|

116

|

12.5 mm

|

AB5 DV P | 1/2" Gm | |

|

MD0030BA

|

30

|

10

|

0.18 kW

|

30 mm

|

58

|

12.5 mm

|

AB8 DV P | 1/2" Gm | |

|

MD0060BA

|

60

|

10

|

0.18 kW

|

30 mm

|

116

|

12.5 mm

|

AB8 DV P | 1/2"Gm | |

|

MD0054BA

|

54

|

8

|

0.18 kW

|

40 mm

|

58

|

12.5 mm

|

AB8 DV P | 1/2" Gm | |

|

MD0108BA

|

108

|

8

|

0.18 kW

|

40 mm

|

116

|

12.5 mm

|

AB8 DV P | 1/2" Gm | |

|

MD0051BA

|

51

|

10

|

0.25 kW

|

30 mm

|

70

|

17.5 mm

|

AB8 DV P | 1/2" Gm | |

|

MD0088BA

|

88

|

10

|

0.25 kW

|

30 mm

|

120

|

17.5 mm

|

AB8 DV P | 1/2" Gm | |

|

MD0092BA

|

92

|

10

|

0.25 kW

|

40 mm

|

70

|

17.5 mm

|

AB8 DV P | 1/2" Gm | |

|

MD0158BA

|

158

|

10

|

0.25 kW

|

40 mm

|

120

|

17.5 mm

|

AB8 DV P | 1/2" Gm | |

|

MD0144BA

|

144

|

7

|

0.25 kW

|

50 mm

|

70

|

17.5 mm

|

AB11 P | 3/4" Gm | |

|

MD0247BA

|

247

|

7

|

0.25 kW

|

50 mm

|

120

|

17.5 mm

|

AB11 P | 3/4" Gm | |

|

MD0174BA

|

174

|

6

|

0.25 kW

|

55 mm

|

70

|

17.5 mm

|

AB13 P | 3/4" Gm | |

|

MD0299BA

|

299

|

6

|

0.25 kW

|

55 mm

|

120

|

17.5 mm

|

AB13 P | 3/4" Gm | |

|

MD0243BA

|

243

|

4

|

0.25 kW

|

65 mm

|

70

|

17.5 mm

|

AB13 P | 3/4" Gm | |

|

MD0418BA

|

418

|

4

|

0.25 kW

|

65 mm

|

120

|

17.5 mm

|

AB13 P | 3/4" Gm |

|

MD-AA

|

*DV: Double ball check valve - A: AISI; **Gm: Gas male |

|

MD-BA

|

*DV: Double ball check valve - P: PVC; **Gm: Gas male USEFUL information for selection of dosing pumps: Max flow rate, Max working pressure, chemical viscosity, specific gravity (S.G.), tem-perature, area classification, suspended solids in chemical. Note: out of standard configuration code shall be indicated only by Etatron authorized staff upon request. |

|

MARCH ȍ

|

¡å Metering Pump

|

MODEL

|

Max Flow

|

Inlet

|

Outlet

|

HP

|

RPM

|

Volts

|

|

cc/min

|

in

|

in

|

|||||

|

210-5

|

1~115

|

1/4"FPT

|

1/4"FPT

|

1/50

|

75

|

115(1¥õ)

|

|

|

210-10

|

5~350

|

1/4"FPT

|

1/4"FPT

|

1/50

|

235

|

115(1¥õ)

|

|

|

212

|

50~1000

|

1/4"FPT

|

1/4"FPT

|

1/50

|

235

|

115(1¥õ)

|

|

MODEL

|

Hz

|

WATTS

|

Àü·ù

|

Motor Type

|

Max int. Press

|

ÃÖ´ëÀ¯Ã¼¿Âµµ

|

|

W

|

A

|

psi

|

¡É(¢µ)

|

|||

|

210-5

|

60

|

50

|

0.8

|

AC

|

160

|

88(190)

|

|

210-10

|

60

|

50

|

0.8

|

AC

|

160

|

88(190)

|

|

212

|

60

|

50

|

0.8

|

AC

|

90

|

88(190)

|

|

PCM ȍ

|

¡ä Diaphragm and plunger dosing pump [ Lagoa _ LG Series ]

|

||||||||||||||||

|

ÀåÁ¡(Benefits)

|

|

||||||||||||||

|

Àû¿ë(Applification)

|

Lagoa-LG series pumps are used in all branches

of industry when products are :

|

|||||||||||||||

|

||||||||||||

|

ÀåÁ¡(Benefits)

|

|

||||||||||

|

Àû¿ë(Applification)

|

P3 series pumps are used in all branches

of industry when products need to be injected at high pressure :

They are also integrated in dosing systems such as Dosyjet for the food industry. |

|||||||||||

|

WILLIAMS ȍ

|

¡å Dual Seal Plunger Metering Pump [ V Series ]

|

Model

(Air/Gas°ø±Þ¾Ð) |

MaxÀ¯·®

|

À¯·®/Stroke

|

Stroke

|

Stroke/min

|

ÃÖ´ëÅäÃâ¾Ð

|

|

GPH/LPH

|

cc

|

in

|

range

|

bar

|

||

| CP125V125(6.9bar) |

0.07/0.27

|

0.1

|

0.5

|

1-45

|

596.4

|

|

| CP250V225(6.9bar) |

0.57/2.16

|

0.8

|

1

|

1-45

|

496.4

|

|

| CP250V300(6.9bar) |

0.57/2.16

|

0.8

|

1

|

1-45

|

903.2

|

|

| CP500V225(6.9bar) |

2.30/8.71

|

3.2

|

1

|

1-45

|

120.7

|

|

| CP500V300(6.9bar) |

2.30/8.71

|

3.2

|

1

|

1-45

|

224.1

|

|

|

CRP500V400

(6.9bar,10.3bar) |

9.08/34.37

|

3.2

|

1

|

1-45

|

434.4

634.3 |

|

|

CRP1000V400

(6.9bar,10.3bar) |

9.04/34.22

7.00/26.50 |

12.7

|

1

|

1-45

|

104.8

158.6 |

|

|

CRP1000V600

(6.9bar,10.3bar) |

8.81/34.22

7.00/26.50 |

12.6

9.8 |

1

|

1-45

1-35 |

234.4

324.0 |

|

|

CRP1000V800

(6.9bar,10.3bar) |

8.81/33.35

6.82/25.81 |

12.3

9.5 |

1

|

1-45

1-35 |

434.4

627.4 |

|

Model

|

MaxÀ¯·®

|

À¯·®/Stroke

|

Stroke

|

Stroke/min

|

ÃÖ´ëÅäÃâ¾Ð

|

|

GPH/LPH

|

cc

|

in

|

range

|

bar

|

||

|

CRP1500W400

|

22.90/86.40

|

36

|

1 1/2"

|

1-40

|

41

|

|

|

CRP1500W600

|

22.90/86.40

|

36

|

1 1/2"

|

1-40

|

134

|

|

|

CRP1500W800

|

22.90/86.40

|

36

|

1 1/2"

|

1-40

|

238

|

|

|

CRP2250W600

|

90.00/336.00

|

160

|

2 1/4"

|

1-35

|

62

|

|

|

CRP1500W400

|

90.00/336.00

|

160

|

2 1/4"

|

1-35

|

124

|

|

Model

|

À¯ ·®

(°¢°¢ÀÇ ¾Ð·Â¿¡ ´ëÇÑ À¯·®)

|

||

|

0 bar

|

103 bar

|

137

bar

|

||

|

LPH

|

LPH

|

LPH

|

||

|

HD 225

|

2.02

|

1.51

|

1.29

|

|

|

HD505

|

8.5

|

7.56

|

6.07

|

|

|

HD1005

|

33.3

|

30.2

|

28.4

|

|

|

Model

|

MaxÀ¯·®

|

À¯·®/St

|

SPM

|

ÃÖ´ëÅäÃâ¾Ð | |

|

Simplex

|

Duplex

|

|||||

|

LPH

|

LPH

|

cc

|

-

|

bar

|

||

|

PD1-316-V

|

2.7

|

5.4

|

1.0

|

1-45

|

6.9

|

|

|

PD2-316-V

|

32.4

|

64.8

|

12.0

|

1-45

|

6.9

|

|

|

PD1-316-V

|

108.0

|

216.0

|

40.0

|

1-45

|

6.9

|

|

|

PD1-TFE-V/TFE

|

2.43

|

4.86

|

0.9

|

1-45

|

6.9

|

|

|

PD2-TFE-V/TFE

|

27.81

|

55.62

|

10.3

|

1-45

|

6.9

|

|

|

PD4-TFE-V/TFE

|

88.83

|

177.66

|

32.9

|

1-45

|

6.9

|

|

|

Model

|

Flow Range

|

Pressure Max

|

|

LPH

|

bar

|

||

|

W 110

|

0.136~9.88

|

10.3

|

|

|

W 111

|

0.123~8.97

|

49.5

|

|

|

W 112

|

0.109~8.02

|

89.3

|

|

|

W 113

|

0.095~6.92

|

137.4

|

|

|

W 120

|

0.265~20.51

|

49.5

|

|

|

W 121

|

0.265~20.51

|

137.4

|

|

|

W 130

|

0.643~52.00

|

49.6

|

|

|

W 131

|

0.643~52.00

|

89.3

|

|

|

W 140

|

1.45~106.13

|

34.5

|

|

|

W 150

|

3.16~189.66

|

20.6

|

|

|

W 160

|

4.65~335.61

|

13.7

|

|

|

W 170

|

5.82~419.00

|

11.0

|

|

Model

|

Flow Range

|

Pressure Max

|

|

LPH

|

bar

|

||

|

W210

|

0.45~22.63

|

10.3

|

|

|

W211

|

0.42~19.98

|

49.5

|

|

|

W212

|

0.34~17.34

|

89.6

|

|

|

W213

|

0.31~14.76

|

137.4

|

|

|

W220

|

1.06~50.95

|

49.5

|

|

|

W221

|

1.06~50.95

|

137.4

|

|

|

W230

|

2.61~123.28

|

49.5

|

|

|

W231

|

2.61~123.28

|

127.6

|

|

|

W240

|

5.34~251.63

|

24.1

|

|

|

W241

|

5.34~251.63

|

62.0

|

|

|

W250

|

10.48~492

|

24.1

|

|

|

W251

|

10.48~492

|

31.0

|

|

|

W260

|

17.0~791

|

20.7

|

|

|

W270

|

21.2~988

|

17.2

|

|

|

W280

|

28.4~1320

|

12.0

|