˘Â

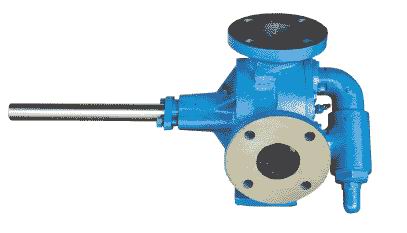

żÜÁ˘ ±âľî ĆßÇÁ(Spur Gear Pump)

.JPG) |

[Specification]

- Temperature Range:

>>> -40ˇÉto

+230ˇÉ / -40˘µto +450˘µ

- Viscosity Range, Single Pumps:

>>> 6.2

cSt to 220,000 cSt / 28 SSU to 1,000,000 SSU

- Viscosity Range, Double Pumps:

>>> 6.2

cSt to 16,500 cSt / 28 SSU to 75,000 SSU

- Differential Pressures:

>>> To

34 BAR / 500 PSI

|

[ Advantage ]

- Enhanced Leak

Protection. Standard

Buna-N O-rings provide positive sealing between sections.

VI-CORR pumps use Viton® O-rings for even greater sealing

between sections.

- Improved

Efficiency. Standard antifriction needle bearings

on all lip seal spur gear pumps reduce torque and improve

efficiency.

- Long

Gear And Shaft Life. Precision-ground, heat-treated

gears and case-hardened steel shafts offer long-life performance.

- Reduced

Equipment Costs. A single power source can

operate both pumping units of a double pump. Plus, each

pumping unit can operate at different pressures for easier

system integration.

- Easy

System Integration. Viking Spur Gear and VI-CORR

Pumps are available with lip seal, mechanical seal, and

Viking Mag Drive® options. Select from one of four 180° port

configurations.

|

|

Spur Gear Pump (¸đµç

»çľç ĹäĂâľĐ 6.9 bar )

|

|

Size

|

Viscosity 100 SSU

|

Viscosity 25,000

SSU

|

|

ĹäĂâ·®

|

ȸŔü

|

Ăâ·Â

|

ĹäĂâ·®

|

ȸŔü

|

Ăâ·Â

|

|

§©/Hr

|

rpm

|

Kw

|

§©/Hr

|

rpm

|

Kw

|

|

SG-0417

|

.009

|

1450

|

.04

|

.01

|

1450

|

.17

|

|

SG-0418

|

.019

|

1450

|

.06

|

.02

|

1450

|

.21

|

|

SG-0425

|

.032

|

1450

|

.07

|

.03

|

1450

|

.24

|

|

SG-0435

|

.045

|

1450

|

.09

|

.05

|

1450

|

.26

|

|

SG-0450

|

.064

|

1450

|

.11

|

.06

|

1450

|

.31

|

|

SG-0470

|

.083

|

1450

|

.14

|

.09

|

1450

|

.34

|

|

SG-0518

|

.12

|

1450

|

.05

|

.14

|

1450

|

.22

|

|

SG-0525

|

.17

|

1450

|

.07

|

.19

|

1450

|

.28

|

|

SG-0535

|

.25

|

1450

|

.09

|

.28

|

1450

|

.32

|

|

SG-0550

|

.38

|

1450

|

.11

|

.4

|

1450

|

.45

|

|

SG-0570

|

.51

|

1450

|

.15

|

.36

|

920

|

.31

|

|

SG-0510

|

.76

|

1450

|

.21

|

.43

|

780

|

.26

|

|

SG-0514

|

1.04

|

1450

|

.28

|

.48

|

640

|

.27

|

|

SG-0519

|

1.3

|

1450

|

.34

|

.59

|

640

|

.37

|

|

SG-0528

|

2.1

|

1450

|

.52

|

.87

|

1450

|

.52

|

|

SG-0729

|

.53

|

1450

|

.20

|

.53

|

1450

|

.6

|

|

SG-0741

|

.76

|

1450

|

.34

|

.77

|

1450

|

.9

|

|

SG-0758

|

1.06

|

1450

|

.37

|

1.1

|

1450

|

1.1

|

|

SG-0782

|

1.51

|

1450

|

.45

|

.98

|

920

|

.9

|

|

SG-0711

|

1.98

|

1450

|

.75

|

1.37

|

920

|

1.2

|

|

SG-0716

|

3.02

|

1450

|

.81

|

1.64

|

780

|

1.1

|

|

SG-0722

|

3.97

|

1450

|

1.3

|

2.55

|

920

|

2.5

|

|

SG-0732

|

5.67

|

1450

|

1.7

|

3.19

|

780

|

2.2

|

|

˘Â żÜÁ˘ ±âľî

ĆßÇÁ(VI-CORR

Pump)

|

[Specification]

- Temperature Range:

>>> -40ˇÉ

to +90ˇÉ / -40˘µto +200˘µ

- Viscosity Range:

>>> 0.8

cSt to 5,500 cSt / 28 SSU to 25,000 SSU

- Differential Pressures:

>>>

To 14 BAR / 200 PSI

|

[ VI-CORR /Spur Gear Applications

]

- Industrial and mobile applications

- Fuel and lubrication

- Filtering

- Metering

- Mixing and blending (Double Pump)

- Special hydraulic applications

|

|

VI-CORR Pump (¸đµç

»çľç ĹäĂâľĐ 6.9 bar )

|

|

Size

|

Viscosity 100 SSU

|

Viscosity 25,000

SSU

|

|

ĹäĂâ·®

|

ȸŔü

|

Ăâ·Â

|

ĹäĂâ·®

|

ȸŔü

|

Ăâ·Â

|

|

§©/Hr

|

rpm

|

Kw

|

§©/Hr

|

rpm

|

Kw

|

|

RP-0518

|

.008

|

1450

|

.06

|

.08

|

920

|

.07

|

|

RP-0525

|

.14

|

1450

|

.06

|

.12

|

920

|

.09

|

|

RP-0535

|

.24

|

1450

|

.09

|

.16

|

920

|

.11

|

|

RP-0550

|

.34

|

1450

|

.13

|

.25

|

920

|

.13

|

|

RP-0570

|

.45

|

1450

|

.20

|

.23

|

640

|

.13

|

|

RP-0510

|

.72

|

1450

|

.23

|

.34

|

640

|

.13

|

|

RP-0514

|

1.0

|

1450

|

.37

|

Consult Factory

|

|

RP-0782

|

1.5

|

1450

|

.63

|

1.1

|

920

|

.63

|

|

RP-0716

|

3.0

|

1450

|

.72

|

1.2

|

920

|

.87

|

|

RP-0724

|

4.5

|

14501450

|

1.3

|

2.9

|

920

|

1.5

|

|

RP-0732

|

6.0

|

1450

|

1.5

|

3.8

|

920

|

1.8

|

|

˘Â ±âľî ĆßÇÁ(180

Series )

|

Series

180 pumps are

designed for handling a variety of fluids while directly connected

to nominal speed motors.

The pump is supplied with a time proven mechanical seal to eliminate

leakage.

A ball bearing handles thrust loading and is not exposed to

liquid pumped.

An integral relief valve can be supplied on request. |

|

Model

|

Port Size

|

Nominal Pump Rating

At 50PSI/345 kPa

100SSU/21CST

|

Motorżä±¸Ăâ·Â

(100SSU/21CST)

|

Max.

Hydro-static

Pressure

|

Max.

ĹäĂâľĐ

|

Max

±ÇŔĺżÂµµ

|

|

50psi/345kpa

(100psi/600kpa)

|

|

In

|

GPM

|

LPM

|

RPM

|

KW(KW)

|

PSI

|

PSI

|

ˇÉ

|

|

F-180

|

1/2 NPT

|

1

|

3.8

|

1200

|

0.19(0.19)

|

400

|

250

|

107

|

|

1/2 NPT

|

1.5

|

5.7

|

1800

|

0.19(0.19)

|

400

|

250

|

107

|

|

FH-180

|

1/2 NPT

|

2.0

|

7.6

|

1200

|

0.19(0.19)

|

400

|

250

|

107

|

|

1/2 NPT

|

3.0

|

11.4

|

1800

|

0.19(0.19)

|

400

|

250

|

107

|

|

˘Â

±âľî ĆßÇÁ(115

Series )

|

These

Series 115

pumps are engineered for small capacity

applications in light and medium service duties.

A greased radial bearing is supplied as a standard to

assure smooth and quiet operation.

The pump is supplied with a multi-ring, stuffing box.

A mechanical seal is available as an optional feature.

Integral relief valve is standard. |

|

Model

|

Port

Size

|

Nominal

Pump Rating

At 50 PSI/345 kPa

100 SSU/21 CST

|

Motorżä±¸Ăâ·Â

(100SSU/21CST)

|

Max.

Hydro-static

Pressure

|

Max.

ĹäĂâľĐ

|

Max

±ÇŔĺżÂµµ

|

|

50psi/345kpa

(100psi/690kpa)

|

Packed

|

Mech.

Seal

|

|

In

|

GPM

|

LPM

|

RPM

|

kW

|

kW

|

PSI

|

PSI

|

ˇÉ

|

ˇÉ

|

|

G-115

|

3/4" NPT

|

6

|

23

|

1200

|

0.26(0.45)

|

400

|

100

|

232

|

99

|

|

9.2

|

35

|

1800

|

0.45(0.71)

|

|

GX2-115

|

1" NPT

|

6

|

23

|

1200

|

0.26(0.45)

|

400

|

100

|

232

|

99

|

|

9.2

|

35

|

1800

|

0.45(0.71)

|

|

H-115

|

1" NPT

|

10

|

38

|

1200

|

0.45(0.82)

|

400

|

100

|

232

|

99

|

|

16

|

61

|

1800

|

0.82(1.40)

|

|

HX4-115

|

1 1/2"

NPT

|

20

|

76

|

1200

|

0.75(1.40)

|

400

|

100

|

232

|

99

|

|

34

|

129

|

1800

|

1.20(2.20)

|

|

˘Â ±âľî ĆßÇÁ(32

Series )

|

The

series 32 Pump is

extremely well suited for light, medium intermittent service

handling a wide range of liquids.

The pump is supplied with a multi-ring, extra deep stuffing

box.

A mechanical seal is available as an optional feature.

A supporting anti-friction bearing pillow block is recommended

for shaft support. Integral relief valve is standard.

|

|

Model

|

Port

Size

|

Nominal

Pump Rating

At 50 PSI/345 kPa

100 SSU/21 CST

|

Motorżä±¸Ăâ·Â

(100SSU/21CST)

|

Max.

Hydro-static

Pressure

|

Max.

ĹäĂâľĐ

|

Max

±ÇŔĺżÂµµ

|

|

50psi/345kpa

(100psi/690kpa)

|

|

In

|

GPM

|

LPM

|

RPM

|

kW

|

kW

|

PSI

|

PSI

|

ˇÉ

|

|

G-32

|

3/4 NPT

|

6

|

23

|

1200

|

0.27

|

(0.50)

|

400

|

100

|

232

|

|

GX2-32

|

1 NPT

|

6

|

23

|

1200

|

0.27

|

(0.50)

|

400

|

100

|

232

|

|

H-32

|

1 NPT

|

10

|

38

|

1200

|

0.50

|

(0.98)

|

400

|

100

|

232

|

|

HX4-32

|

1 1/2 NPT

|

20

|

76

|

1200

|

0.77

|

(1.31)

|

400

|

100

|

232

|

|

J-32

|

1 1/2 NPT

|

20

|

76

|

420

|

0.98

|

(1.88)

|

400

|

100

|

232

|

|

K-32

|

2 NPT

|

42

|

159

|

420

|

1.50

|

(3.0)

|

400

|

100

|

232

|

|

KK-32

|

2 NPT

|

55

|

208

|

420

|

1.73

|

(3.53)

|

400

|

100

|

232

|

|

L-32

|

2 NPT

|

94

|

356

|

420

|

2.85

|

(5.85)

|

400

|

100

|

232

|

|

LQ-32

|

3 ANSI

|

94

|

356

|

420

|

2.85

|

(5.85)

|

400

|

100

|

232

|

|

LL-32

|

3 ANSI

|

143

|

541

|

520

|

4.5

|

(9.38)

|

400

|

100

|

232

|

|

Q-32

|

4 ANSI

|

205

|

776

|

350

|

7.5

|

(~)

|

400

|

75

|

232

|

|

M-32

|

4 ANSI

|

290

|

1098

|

280

|

10.28

|

(~)

|

400

|

75

|

232

|

|

N-32

|

5 ANSI

|

480

|

1817

|

280

|

17.15

|

(~)

|

400

|

75

|

232

|

|

R-32

|

6 ANSI

|

740

|

2801

|

190

|

25.50

|

(~)

|

400

|

75

|

232

|

|

˘Â ±âľî ĆßÇÁ(90

Series )

|

The

series 90 line

of pumps combine a compact design with a positive smooth flow.

They are designed to be mounted directly on the motor's drive

shaft thus eliminating the need for couplings, bases, gearboxes

or outboard bearings.

These general-purpose pumps are available with lip seals or

self-adjusting mechanical seals.

An integral valve can be supplied on request. |

|

Model

|

Port

Size

|

Nominal

Pump Rating

At 50 PSI/345 kPa

100 SSU/21 CST

|

Motorżä±¸Ăâ·Â

(100SSU/21CST)

|

Max.

Hydro-static

Pressure

|

Max.

ĹäĂâľĐ

|

Max

±ÇŔĺżÂµµ

|

|

50psi/345kpa

(100psi/690kpa)

|

|

In

|

GPM

|

LPM

|

RPM

|

kW

|

kW

|

PSI

|

PSI

|

ˇÉ

|

|

G-90L

|

1 NPT

|

5

|

19

|

1200

|

0.37

|

(0.56)

|

400

|

50

|

107

|

|

7

|

27

|

1800

|

|

GG-90L

|

1 NPT

|

7

|

27

|

1200

|

0.37

|

(0.56)

|

400

|

50

|

107

|

|

10

|

38

|

1800

|

|

H-90L

|

1 1/2 NPT

|

10

|

38

|

1200

|

0.37

|

(0.75)

|

400

|

50

|

107

|

|

15

|

57

|

1800

|

|

HJ-90L

|

1 1/2 NPT

|

13

|

49

|

1200

|

0.75

|

(1.10)

|

400

|

50

|

107

|

|

20

|

76

|

1800

|

|

HL-90L

|

1 1/2 NPT

|

20

|

76

|

1200

|

1.10

|

(1.50)

|

400

|

50

|

107

|

|

30

|

114

|

1800

|

|

G-90M

|

1 NPT

|

5

|

19

|

1200

|

0.37

|

(0.56)

|

400

|

100

|

107

|

|

7

|

27

|

1800

|

|

GG-90M

|

1 NPT

|

7

|

27

|

1200

|

0.37

|

(0.56)

|

400

|

100

|

107

|

|

10

|

38

|

1800

|

|

H-90M

|

1 1/2 NPT

|

10

|

38

|

1200

|

0.37

|

(0.75)

|

400

|

100

|

107

|

|

15

|

57

|

1800

|

|

HJ-90M

|

1 1/2 NPT

|

13

|

49

|

1200

|

0.75

|

(1.10)

|

400

|

100

|

107

|

|

20

|

76

|

1800

|

|

HL-90M

|

1 1/2 NPT

|

20

|

76

|

1200

|

1.10

|

(1.50)

|

400

|

100

|

107

|

|

30

|

114

|

1800

|

|

˘Â

±âľî ĆßÇÁ(230 Series

)

|

The

Series 230

jacketed pumps are specifically designed

to handle heavy, viscous liquid requiring temperature control

to maintain a following state.

Series 230 pumps can be supplied with jacketed casing, head,

rotor bearing sleeve and integral relief valve.

Packing gland is multi-ring and can be supplied with special

packing for high temperature conditions, when required. |

|

Model

|

Port

Size

|

Nominal

Pump Rating

At 50 PSI/345 kPa

100 SSU/21 CST

|

Motorżä±¸Ăâ·Â

(100SSU/21CST)

|

Max.

Hydro-static

Pressure

|

Max.

ĹäĂâľĐ

|

Max

±ÇŔĺżÂµµ

|

|

50psi/345kpa

(100psi/690kpa)

|

|

In

|

GPM

|

LPM

|

RPM

|

kW

|

kW

|

PSI

|

PSI

|

ˇÉ

|

|

HX4-230

|

1 1/2 NPT

|

20

|

76

|

1200

|

0.77

|

(1.31)

|

400

|

100

|

232

|

|

KK-230

|

2 NPT

|

55

|

208

|

420

|

1.73

|

(3.53)

|

400

|

100

|

232

|

|

LQ-230

|

3 ANSI

|

94

|

356

|

420

|

2.85

|

(5.85)

|

400

|

100

|

232

|

|

Q-230

|

4 ANSI

|

205

|

776

|

350

|

7.50

|

(~)

|

400

|

75

|

232

|

|

M-230

|

5 ANSI

|

290

|

1098

|

280

|

10.28

|

(~)

|

400

|

75

|

232

|

|

N-230

|

5 ANSI

|

480

|

1817

|

280

|

15.75

|

(~)

|

400

|

75

|

232

|

|

˘Â ±âľî ĆßÇÁ(260

Series )

|

The

Series 260

jacketed pumps are designed to handle

heavy viscous liquids requiring temperature control.

They are a jacketed version of the 332 series pumps.

These pumps are available with jacketed casing, head, rotor

bearing sleeve and integral relief valve. |

|

Model

|

Port

Size

|

Nominal

Pump Rating

At 50 PSI/345 kPa

100 SSU/21 CST

|

Motorżä±¸Ăâ·Â

(100SSU/21CST)

|

Max.

Hydro-static

Pressure

|

Max.

ĹäĂâľĐ

|

Max

±ÇŔĺżÂµµ

|

|

50psi/345kpa

(100psi/690kpa)

|

|

In

|

GPM

|

LPM

|

RPM

|

kW

|

kW

|

PSI

|

PSI

|

ˇÉ

|

|

Q-260

|

4 ANSI

|

310

|

1173

|

520

|

12.7

|

(20.1)

|

400

|

200

|

232

|

|

M-260

|

5 ANSI

|

400

|

1514

|

420

|

16.4

|

(27.0)

|

400

|

200

|

232

|

|

N-260

|

5 ANSI

|

590

|

2233

|

350

|

22.4

|

(37.3)

|

400

|

125

|

232

|

|

˘Â ±âľî ĆßÇÁ(115SS

& 124SS Series )

|

The

Series 115SS and 124SS

are ideal for most demanding pumping applications

that require stainless steel construction.

These pumps are offered with all wetted part of 316 stainless

steel and with idlers of non-galling 770 alloy.

This line of heavy duty pumps provides long life and trouble-free

operation for the chemical, petrochemical, food and other process

and general industries.

They are designed to accept either packing or mechanical seals

to minimize liquid loss and for shaft protection.

With the revolvable casing they provide increased versatility

of installation. |

|

Model

|

Port

Size

|

Nominal

Pump Rating

At 50 PSI/345 kPa

100 SSU/21 CST

|

Motorżä±¸Ăâ·Â

(100SSU/21CST)

|

Max.

Hydro-static

Pressure

|

Max.

ĹäĂâľĐ

|

Max

±ÇŔĺżÂµµ

|

|

50psi/345kpa

(100psi/690kpa)

|

|

In

|

GPM

|

LPM

|

RPM

|

kW

|

kW

|

PSI

|

PSI

|

ˇÉ

|

|

H-115SS

|

1.5 NPT

|

10

|

40

|

1200

|

0.56

|

1.10

|

400

|

100

|

149

|

|

HX4-115SS

|

1.5 NPT

|

20

|

80

|

1200

|

0.75

|

1.50

|

400

|

100

|

149

|

|

K-124SS

|

2 ANSI

|

45

|

180

|

520

|

1.50

|

3.73

|

400

|

100

|

149

|

|

KK-124SS

|

2 ANSI

|

65

|

260

|

520

|

2.24

|

3.73

|

400

|

100

|

149

|

|

LQ-124SS

|

2.5 ANSI

|

90

|

360

|

420

|

3.73

|

7.46

|

400

|

100

|

149

|

|

LL-124SS

|

3 ANSI

|

110

|

440

|

420

|

3.73

|

7.46

|

400

|

100

|

149

|

|

˘Â ±âľî ĆßÇÁ(115CS

& 124CS Series )

|

The

Series 115CS and 124CS

series of pumps are often used for

pumping applications that involve extra strength, shock resistance

or other safety contingencies.

The steel used in the manufacture of these pumps meets ASTM

designation A216 Grade WCB specification making it ideal for

uses in refineries, petrochemical and chemical process plants.

They are also utilized in may other processes and general industries

where their rugged construction and smooth positive displacement

action deliver positive flow and low shear transmission.

They are furnished as standard with either packing or mechanical

seals and all pumps have revolvable casings for port selection.

|

|

Model

|

Port

Size

|

Nominal

Pump Rating

At 50 PSI/345 kPa

100 SSU/21 CST

|

Motorżä±¸Ăâ·Â

(100SSU/21CST)

|

Max.

Hydro-static

Pressure

|

Max.

ĹäĂâľĐ

|

Max

±ÇŔĺżÂµµ

|

|

50psi/345kpa

(100psi/690kpa)

|

|

In

|

GPM

|

LPM

|

RPM

|

kW

|

kW

|

PSI

|

PSI

|

ˇÉ

|

|

H-115CS

|

1.5 NPT

|

15

|

60

|

1800

|

1.10

|

1.50

|

400

|

100

|

149

|

|

HX4-115CS

|

1.5 NPT

|

30

|

120

|

1800

|

1.50

|

2.24

|

400

|

100

|

149

|

|

K-124CS

|

2 ANSI

|

60

|

240

|

640

|

2.24

|

5.60

|

400

|

100

|

149

|

|

KK-124CS

|

2 ANSI

|

80

|

320

|

640

|

3.73

|

5.60

|

400

|

100

|

149

|

|

LQ-124CS

|

2.5 ANSI

|

135

|

540

|

640

|

5.60

|

11.19

|

400

|

100

|

149

|

|

LL-124CS

|

3 ANSI

|

140

|

560

|

520

|

5.60

|

11.19

|

400

|

100

|

149

|

|

˘Â ±âľî ĆßÇÁ(190

Series )

|

These

Series 190

pumps are designed to operate at nominal motor

speeds.

Ball bearings are heavy duty, grease lubricated type, oversized

to withstand excessive thrust and radial loads while maintaining

perfect shaft and rotor alignment.

Pump is supplied with mechanical seal and "O" ring gasketing.

The idler bushing is made of self-lubricating carbon material

assuring trouble free operation. Integral relief valve

is standard. |

|

Model

|

Port

Size

|

Nominal

Pump Rating

At 50 PSI/345 kPa

100 SSU/21 CST

|

Motorżä±¸Ăâ·Â

(100SSU/21CST)

|

Max.

Hydro-static

Pressure

|

Max.

ĹäĂâľĐ

|

Max

±ÇŔĺżÂµµ

|

|

50psi/345kpa

(100psi/690kpa)

|

|

In

|

GPM

|

LPM

|

RPM

|

kW

|

kW

|

PSI

|

PSI

|

ˇÉ

|

|

GG-190

|

1

NPT

|

10.0

|

38

|

1800

|

0.46

|

0.75

|

0.75

|

250

|

107

|

|

7.0

|

26

|

1200

|

0.30

|

0.46

|

0.46

|

|

HJ-190

|

1 1/2

NPT

|

20.0

|

76

|

1800

|

0.90

|

1.57

|

1.57

|

250

|

107

|

|

13.0

|

49

|

1200

|

0.56

|

0.97

|

0.97

|

|

HL-190

|

1 1/2

NPT

|

30.0

|

114

|

1800

|

1.35

|

1.95

|

1.95

|

250

|

107

|

|

20.0

|

76

|

1200

|

0.75

|

1.20

|

1.20

|

|

AS-190

|

2 1/2

NPT

|

35.0

|

125

|

1200

|

1.20

|

1.95

|

1.95

|

250

|

107

|

|

AK-190

|

2 1/2

NPT

|

50.0

|

189

|

1200

|

2.02

|

3.07

|

3.07

|

250

|

107

|

|

˘Â ±âľî ĆßÇÁ(124

Series )

|

The

Series 124

pump is designed and engineered for

heavy-duty liquid transfer applications.

The bearing housing is precision cast and accurately machined

to assure positive pump and bearing alignment.

The ball bearing is heavy duty, grease-lubricating type, oversized

to withstand excessive thrust and radial loads.

Pump can be supplied with either packing or mechanical

seal.

Integral relief valve is standard.

Jacketed features are available. |

|

Model

|

Port

Size

|

Nominal

Pump Rating

At 50 PSI/345 kPa

100 SSU/21 CST

|

Motorżä±¸Ăâ·Â

(100SSU/21CST)

|

Max.

Hydro-static

Pressure

|

Max.

ĹäĂâľĐ

|

Max

±ÇŔĺżÂµµ

|

|

50psi/345kpa

(100psi/690kpa)

|

Packed

|

Mech.

Seal

|

|

In

|

GPM

|

LPM

|

RPM

|

kW

|

kW

|

PSI

|

PSI

|

ˇÉ

|

|

J-124

|

1 1/2 NPT

|

30

|

114

|

640

|

1.1

|

2.2

|

400

|

200

|

232

|

99

|

|

K-124

|

2 NPT

|

63

|

238

|

640

|

2.2

|

4.5

|

400

|

200

|

232

|

99

|

|

KK-124

|

2 NPT

|

84

|

318

|

640

|

3.0

|

5.3

|

400

|

200

|

232

|

99

|

|

L-124

|

2 NPT

|

140

|

530

|

640

|

5.2

|

9.3

|

400

|

200

|

232

|

99

|

|

LQ-124

|

3 ANSI

|

140

|

530

|

640

|

5.2

|

9.3

|

400

|

200

|

232

|

99

|

|

LL124-

|

3 ANSI

|

138

|

522

|

640

|

4.7

|

8.6

|

400

|

200

|

232

|

99

|

|

LM-124

|

3 ANSI

|

55

|

795

|

640

|

4.9

|

9.0

|

400

|

200

|

232

|

99

|

|

˘Â ±âľî ĆßÇÁ(332

Series )

|

The

Series 332

pump has been developed for high capacity and

heavy-duty service for a wide range of pump applications.

Heavy-duty roller bearing is grease lubricated, oversized to

withstand excessive thrust and radial loads.

Packing is supplied as standard, mechanical seals can be supplied,

when required. Integral relief valve is standard.

Jacketed features are available - see Series 260. |

|

Model

|

Port

Size

|

Nominal

Pump Rating

At 50 PSI/345 kPa

100 SSU/21 CST

|

Motorżä±¸Ăâ·Â

(100SSU/21CST)

|

Max.

Hydro-static

Pressure

|

Max.

ĹäĂâľĐ

|

Max

±ÇŔĺżÂµµ

|

|

50psi/345kpa

(100psi/690kpa)

|

Packed |

Mech.

Seal |

|

In

|

GPM

|

LPM

|

RPM

|

kW

|

kW

|

PSI

|

PSI

|

ˇÉ

|

|

Q-332

|

4 ANSI

|

310

|

1173

|

520

|

12.7

|

20.1

|

400

|

200

|

232

|

99

|

|

M-332

|

4 ANSI

|

400

|

1514

|

420

|

16.4

|

27.0

|

400

|

200

|

232

|

99

|

|

N-332

|

5 ANSI

|

590

|

2233

|

350

|

22.4

|

37.3

|

400

|

125

|

232

|

99

|

|

R-332

|

6 ANSI

|

700

|

2650

|

190

|

27.0

|

43.2

|

400

|

125

|

232

|

99

|

|